Technical Specifications

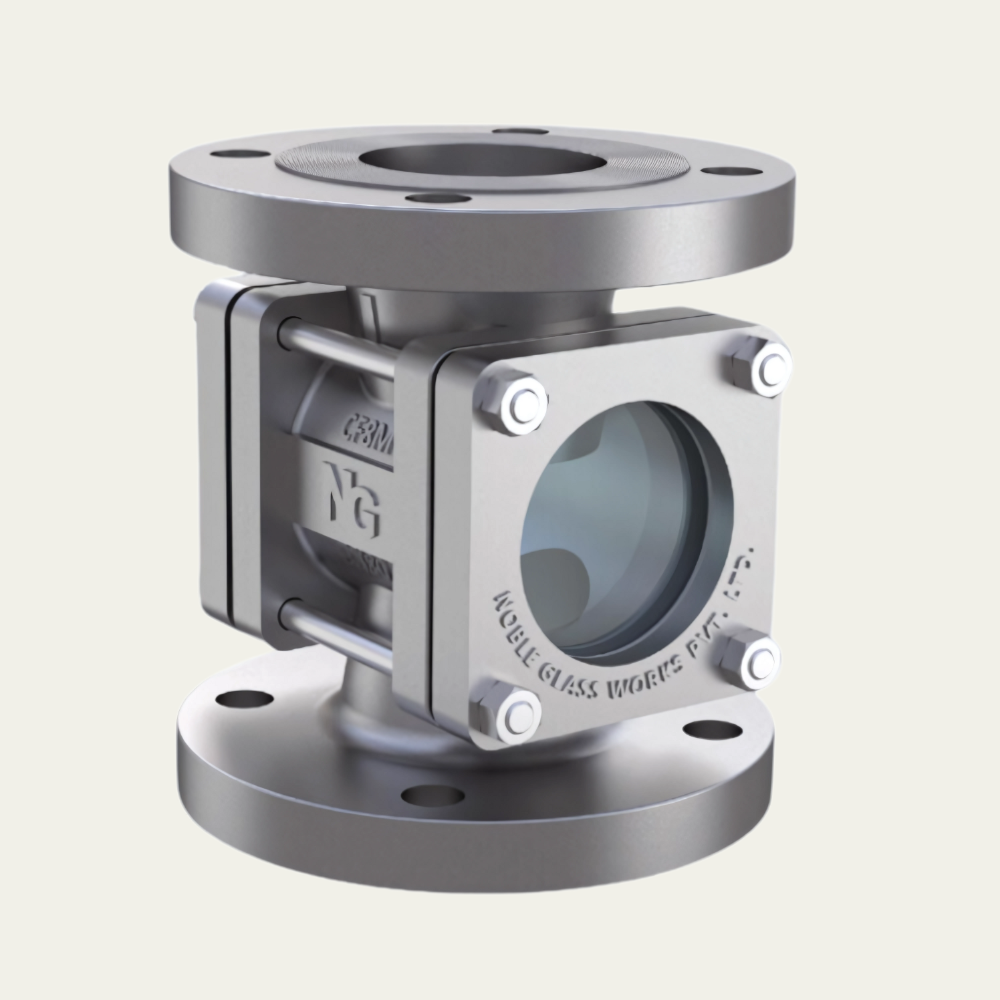

Materials: Covers and weld pads are available in durable options like SS 304, SS 316, SS 316L, and Carbon Steel, offering strength and corrosion resistance.

Lenses: Include Toughened Borosilicate Glass for high temperatures, Soda Lime Glass for economical low-pressure applications, Polycarbonate for impact resistance, and Acrylic for lightweight clarity.

Gaskets: Seal and cushion gaskets come in Non-Asbestos, Nitrile, Silicone, PTFE, and Viton, providing adaptability for chemical and temperature needs.

Fasteners: Made from Stainless Steel or Alloy Steel, ensuring secure installation.

Performance: Operates in temperatures from -60°C to +250°C and pressures up to 40 bar, with distortion-free viewing for clear process observation.

Customization: Sizes range from 25NB to 300NB, with options tailored for vacuum and extreme conditions.