Technical Specification

Maintenance – Strainer maintenance should be made at least once per year, or whenever the pressure drop is found to be

in excess of normal figures. For a complete maintenance guide follow the points below:

- Ensure the main line has been isolated.

- Untighten cover stud bolts & nuts, remove cover & gasket.

- Withdraw basket and carefully inspect for damage.

- Clean any obstructed holes in the screen. If basket is damaged replace with new basket.

- Carefully clean the inside of the basket strainer body.

- Fit new gasket.

- Install the cleaned or replacement basket.

- Fit cover and tighten stud bolts & nuts to recommended torques.

- Slowly introduce line pressure checking for leaks as pressure is increased to normal.

- Mark the strainer cover with date of maintenance performed.

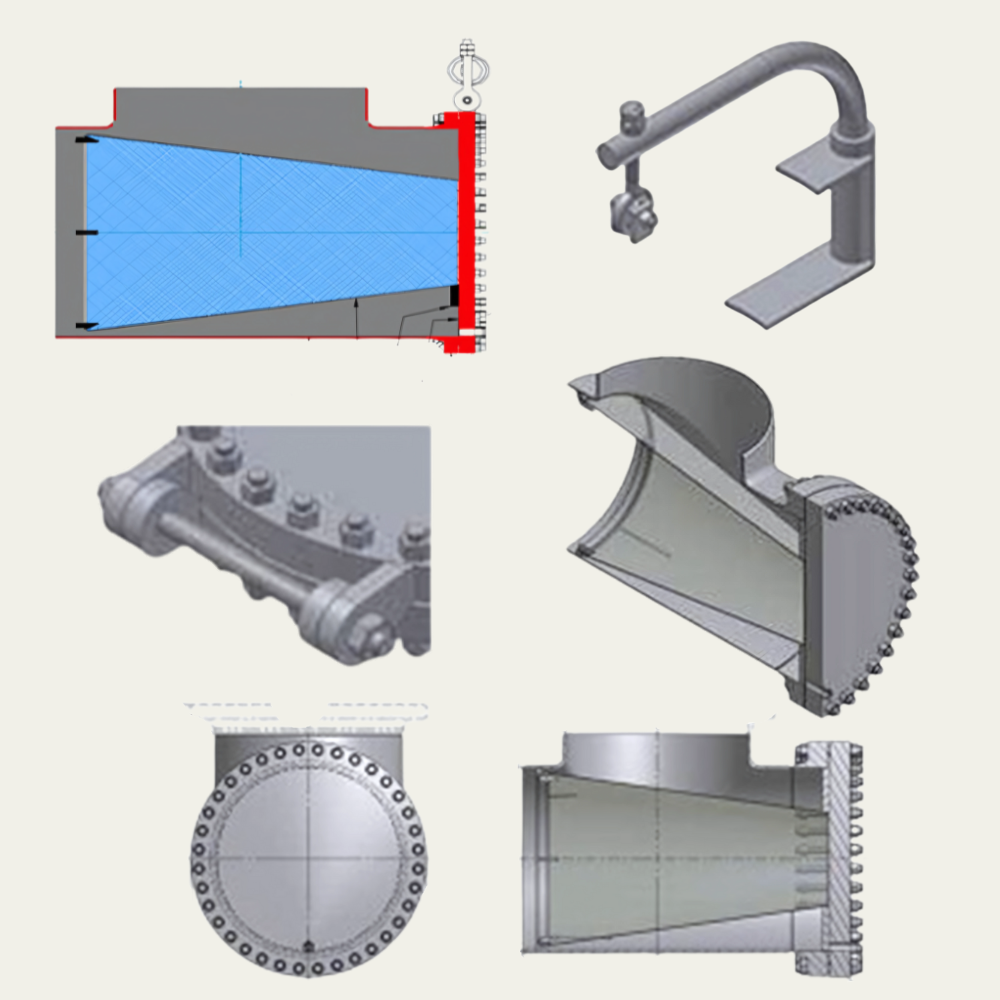

| POS. | DESCR. | MAT. | SPARE |

| 1 | BODY | ACC TO M.R. | |

| 2 | FLANGE | ||

| 3 | COVER | ||

| 4 | BASKET | X | |

| 5 | GUIDE RODS | ||

| 6 | GASKET | X | |

| 7 | BOLTING | ||

| 8 | DRAIN | ||

| 9 | HINGE* | ||

| 10 | DAVIT* |

| SIZE | S | L2 | L1 | L | O | |||||||||||||||

| RATING | 150 | 300 | 600 | 900 | 1500 | 2500 | 150 | 300 | 600 | 900 | 1500 | 2500 | 150 | 300 | 600 | 900 | 1500 | 2500 | ||

| 2″ | 127 | 63,5 | 258 | 271 | 290 | 347 | 398 | 152 | 162 | 181 | 222 | 260 | 152 | 165 | 165 | no | 216 | 235 | ||

| 21/2″ | 152 | 76,2 | 296 | 309 | 328 | 379 | 455 | 174 | 184 | 203 | 241 | 295 | 178 | 190 | 190 | no | 244 | 267 | ||

| 3″ | 171 | 85,7 | 315 | 334 | 353 | 391 | 423 | 525 | 186 | 200 | 219 | 244 | 270 | 339 | 190 | 210 | 210 | 241 | 267 | 305 |

| 4″ | 210 | 105 | 366 | 385 | 430 | 455 | 474 | 607 | 211 | 228 | 263 | 282 | 301 | 390 | 229 | 264 | 273 | 292 | 311 | 356 |

| 5″ | 248 | 124 | 429 | 448 | 493 | 518 | 576 | 722 | 243 | 263 | 301 | 320 | 371 | 463 | 254 | 279 | 330 | 349 | 375 | 419 |

| 6″ | 286 | 143 | 467 | 486 | 537 | 582 | 645 | 848 | 263 | 284 | 327 | 357 | 416 | 543 | 279 | 318 | 356 | 381 | 394 | 483 |

| 8″ | 356 | 178 | 563 | 582 | 639 | 696 | 798 | 1007 | 314 | 336 | 386 | 422 | 501 | 641 | 343 | 381 | 419 | 470 | 483 | 552 |

| 10″ | 432 | 216 | 639 | 671 | 753 | 817 | 957 | 1287 | 354 | 387 | 451 | 489 | 597 | 819 | 406 | 444 | 508 | 546 | 584 | 673 |

| 12″ | 508 | 254 | 741 | 772 | 836 | 925 | 1090 | 1452 | 406 | 441 | 495 | 552 | 679 | 921 | 483 | 521 | 559 | 610 | 673 | 762 |

| 14″ | 559 | 279 | 817 | 849 | 908 | 1001 | 1173 | 447 | 482 | 533 | 597 | 730 | 533 | 584 | 603 | 641 | 749 | |||

| 16″ | 810 | 305 | 868 | 906 | 982 | 1058 | 1249 | 474 | 514 | 578 | 628 | 781 | 597 | 648 | 686 | 705 | 826 | |||

| 18″ | 686 | 343 | 969 | 1007 | 1071 | 1160 | 1357 | 528 | 568 | 629 | 692 | 851 | 635 | 711 | 743 | 787 | 914 | |||

| 20″ | 762 | 381 | 1055 | 1090 | 1160 | 1274 | 1490 | 574 | 612 | 679 | 756 | 933 | 698 | 775 | 813 | 857 | 984 | |||

| 24″ | 884 | 432 | 1172 | 1204 | 1287 | 1465 | 1693 | 638 | 676 | 755 | 882 | 1060 | 813 | 914 | 940 | 1041 | 1168 | |||

| CONNECTIONS | |

| BUTTWELD | ASME B16.25 |

| FLANGED | ASME B16.5 |