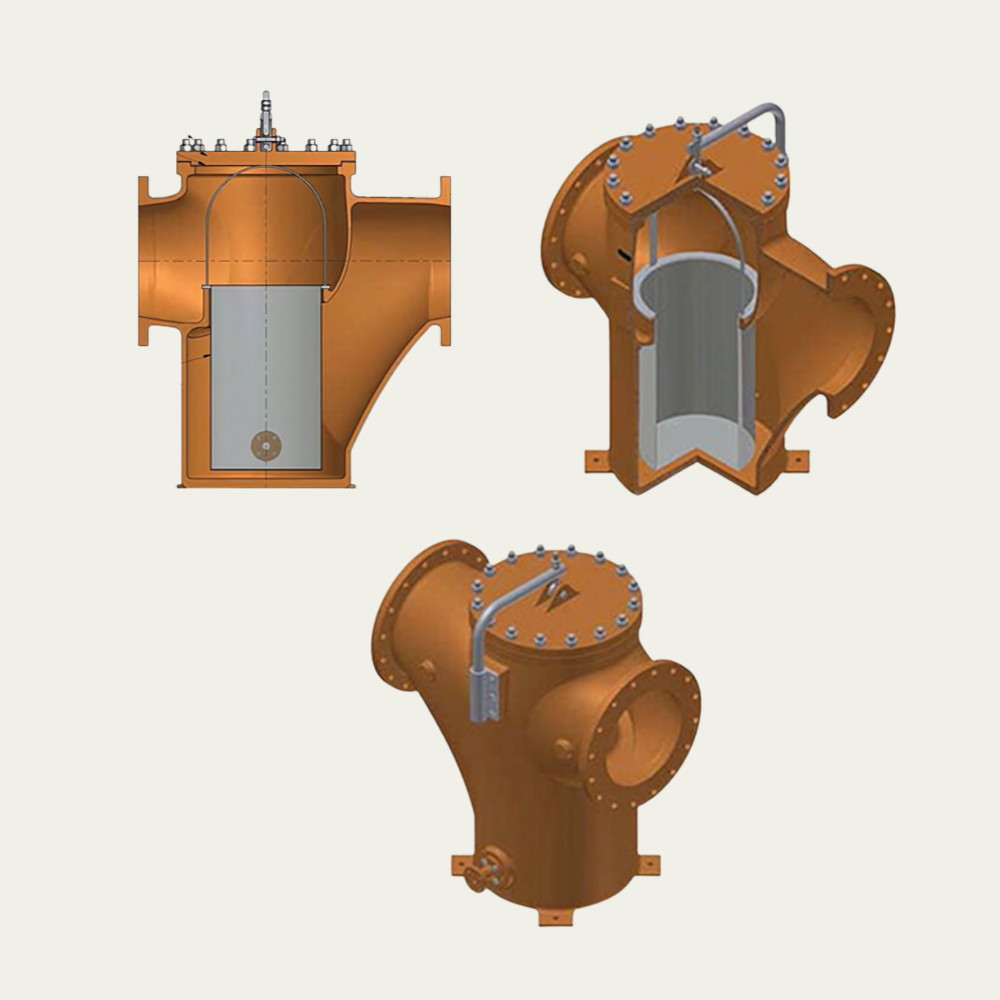

Designed to ASME B16.34 the strainer bodies are produced with a superior wall thickness for corrosion allowance. Standard strainers are equipped with screens for the average service of most mediums (steam, gas, air, oil, chemicals etc). The large screen open area ensures an efficient filtering action with a low pressure drop. Filtering area to inlet area ratio is larger than 3:1. Screens are manufactured with perforated plate in the materials and with the perforation specified in the relevant tables. Different filtration or materials are available on request.

- All strainers should be installed as close as possible to the machinery which they are being installed to protect. It is important to ensure that the strainer is installed with the flow following the same direction as the flow direction arrow cast onto the body

- For mounting in horizontal or inclined pipelines ensure that the screen housing is always mounted below the pipeline

“Y” strainers should never be mounted in vertical pipelines in the upward flow condition.

Download Specifications