Technical Specification

| Size Range | 2” ~240” (DN50~DN6000) |

| Class Range | 150Lb~2500Lb (PN10~PN420) |

| Design Standard | API 609, ASME B16.34, API607, BS EN-593 |

| End Connection | RF/ RTJ – ASME B16.5 / B16.47; BW – ASME B16.25; Wafer |

| F – F Dimension | ASME B16.10 |

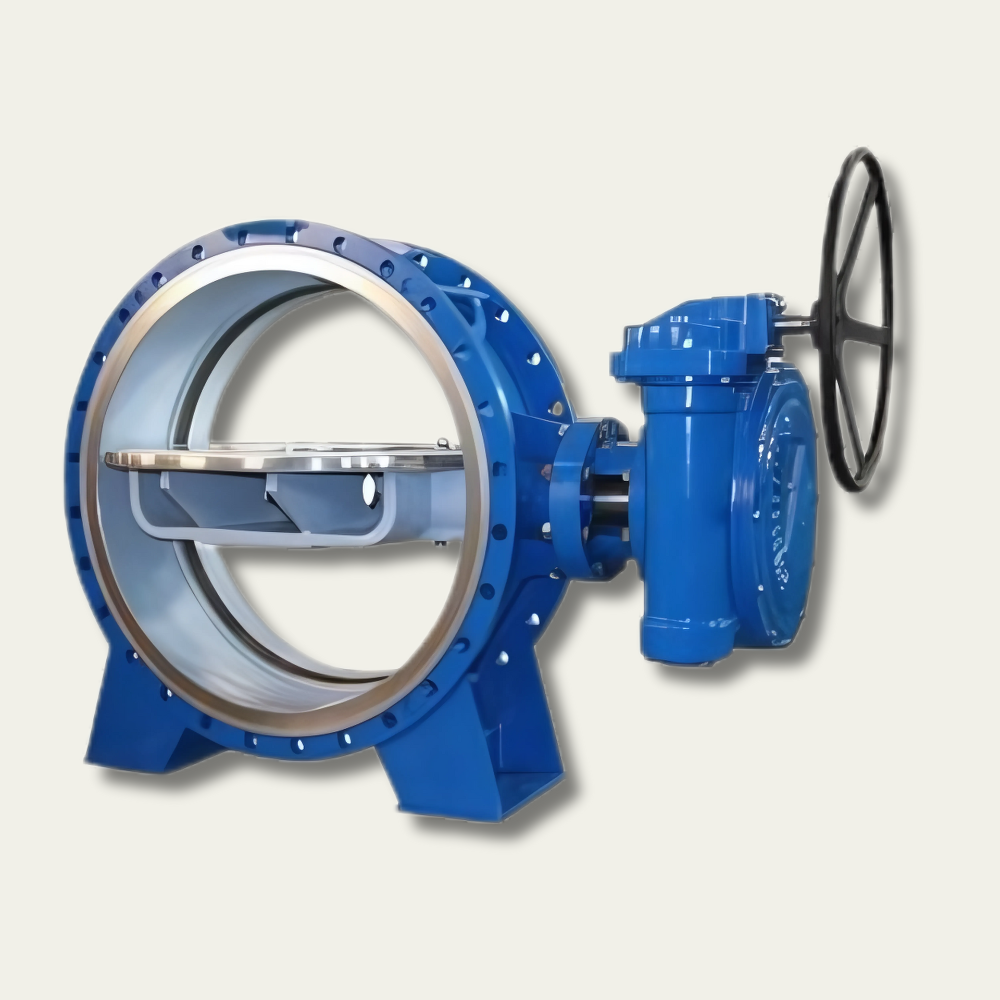

| Construction | Concentric/Double/Triple Offset, Wafer/Lug/Double Flange, Soft/Metal Seat, Sleeved/Lined, Unidirectional/ Bidirectional Seal |

| Design Features | Emergency Sealant Injection; Vent & Drain; Antistatic; Blowout Proof Stem; Fire Safe (As Per API 607) |

| Seat Seal Options | EPDM, NBR, PTFE, Metal Seats, Viton |

| Temperature Limits | -40°C to 200°C (EPDM), -30°C to 120°C (NBR), -40°C to 260°C (PTFE), -29°C to 538°C (Metal Seats) |

| Special | NACE; Cryogenic; Extended Stem; Fugitive Emission |

| Inspections & Tests |

API 598 BS EN 12266-1 |

| Material | Forged & Cast CS, LTCS, SS, AS and Special Steel, Cast Iron |

| Applications | Oil & Gas, Chemicals, Waters, Power, Marine, Mining, etc. |