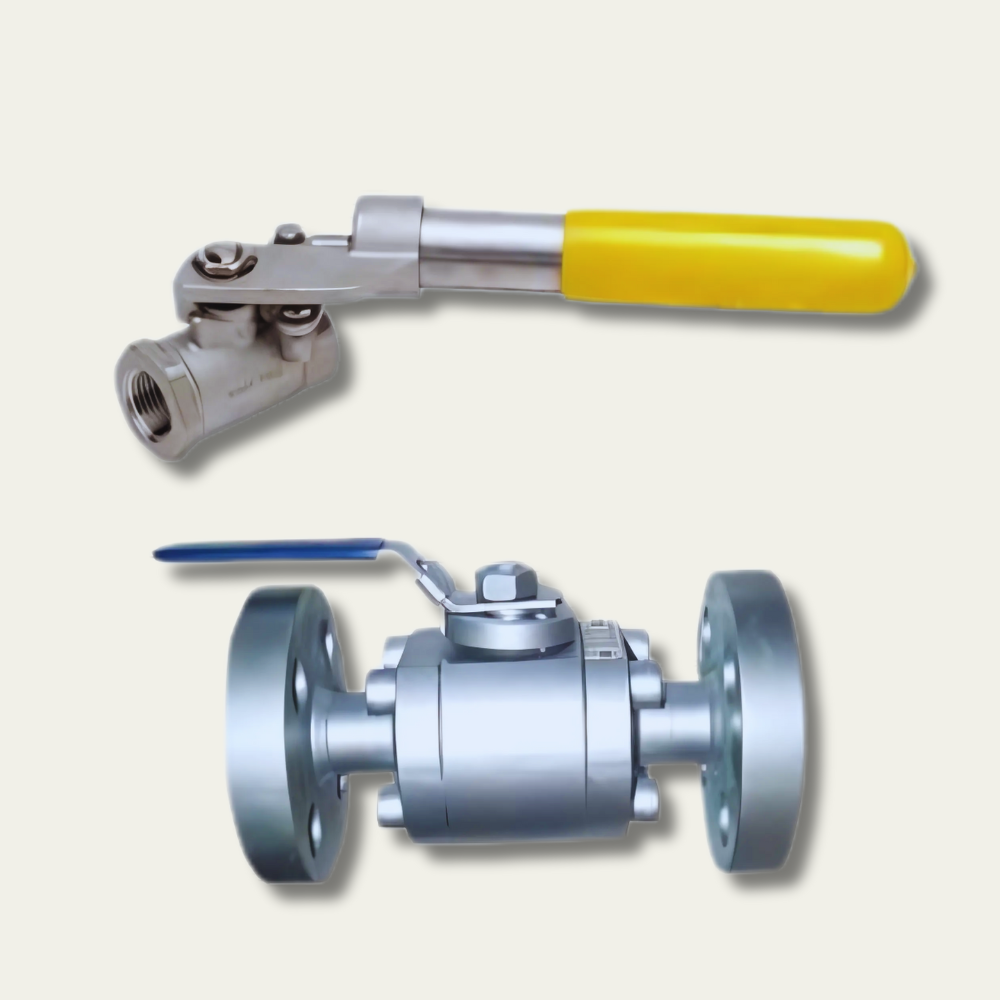

Technical Specification

| Size Range | 1/2” ~2” (DN15~DN50) (Forged);

1/2” ~8” (DN15~DN200) (Cast) |

| Class Range | 150Lb~2500Lb (PN10~PN420) (Forged);

150Lb~300Lb (PN10~PN40) (Cast) |

| Actuation Options | Manual, Gear, Pneumatic, Electric and Deadman handle (available up to 50mm) |

| Design Standard | API 6D, API 608, ISO 17292, ASME B16.34 |

| End Connection | RF/ RTJ – ASME B16.5 / B16.47; BW – ASME B16.25; SW/ NPT – ASME B16.11, B1.20.1 |

| F – F Dimension | ASME B16.10 |

| Construction | FB/RB; 1/2/3PCS Body; 2/3/4 Way; Soft/Metal Seat; Side/Top Entry |

| Design Features | DBB; Relief Cavity; Emergency Sealant Injection; Vent & Drain; Antistatic; Blowout Proof Stem; Fire Safe (As Per API 607) |

| Special | NACE; Cryogenic; Extended Stem; Fugitive Emission; Lip Seal |

| Material | WCB/WCC, A105, LF2, WC6, LCB, LCC, CF3M, CF8M, CF3, CF8, 316, 304, Duplex, Titanium & other exotic alloys. |

| Applications | Oil & Gas, Chemicals, Waters, Power, Marine, Mining, etc. |

Salient Features:

- Fire-safe to ISO 10497 and API 607

- Mirror-finished solid stainless ball

- Fine-grained PTFE and RPTFE seats

- Cavity Pressure Relief mechanism

- Blowout-proof stem

- High integrity stem sealing – Belleville springs compensate for wear and thermal expansions

- Antistatic feature

- Actuator-mounting flange conforms to ISO 5211

- Compliance with Jet Fuel and Defence applications

Versatile Range:

- One, two- and three-piece constructions

- Full-bore and reduced-bore designs

- Soft and metal-seated

- Top and Side Entry Options

- Offered in carbon steel, stainless steel and duplex stainless steels

- Screwed, socket-weld and flanged ends

- ASME classes up to 2500

- Variety of actuatior integration